Western New England Competition

Last weekend, Team 467 attended our 2nd competition of the year, held on the campus of Western New England University in Springfield, MA.

We had a fantastic event - finishing qualifying matches in 4th place and leading the 3rd Alliance into the elimination round, where we made it to the semifinals before being knocked out. Major kudos to our alliance partners 178 (The 2nd Law Enforcers from Farmington, CT) and 8046 (Lakerbots, from Meredith, NH) for forming such a fantastic New England alliance with us.

[Read More]Southern Maine Competition

Travel Trip Highlight Reel

Week Eight Update

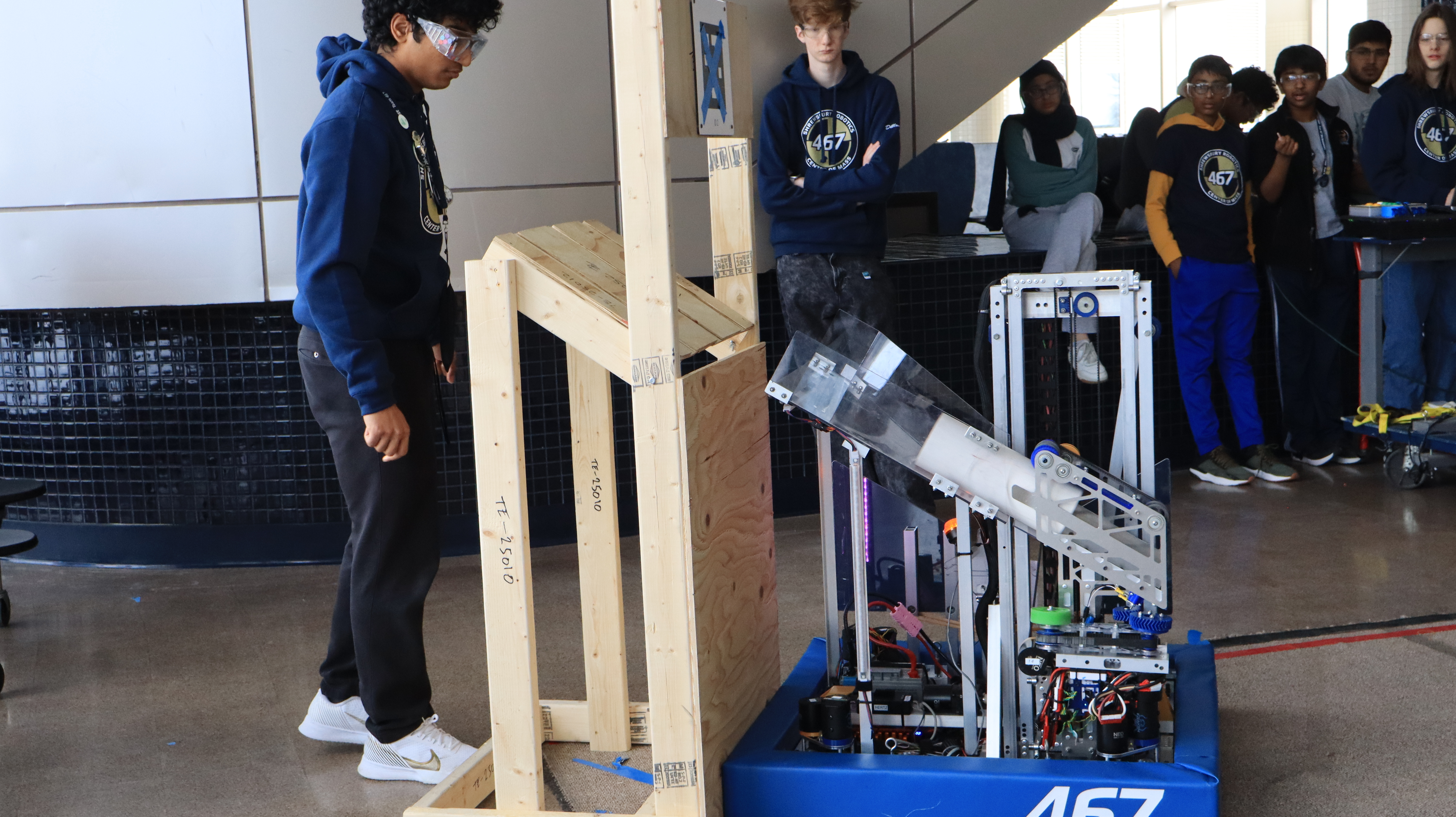

This was our final week to work on the robot before our first competition in Southern Maine and team 467 is not stopping.

The mechanical team is working to iron out our climbing mechanism to have a consistent climb, making minor adjustments to the elevator to ensure its consistency for competition, and adjusting the angle of the hopper to ensure that coral won’t get jammed between the effector and hopper.

[Read More]2025 Impact Award Video Submission

We are please to share our video submission for this years Impact Award.

2025 Robot Reveal

Week Seven Update

One week out from Southern Maine and it’s crunch time for 467. We’ve been working endlessly over the school break to make our robot competition ready.

Our mechanical team has fixed issues with our elevator to ensure it can withstand rapid movement and made minor adjustments to the climber to ensure its consistency. The programming team took control of the robot. They were able to finalize the drive controls and started on automatic scoring alignment to aid driving. The electrical team mounted and wired up our LEDs which will allow the drive team to communicate and react faster. The impact award presenters are doing mock presentations to mentors and we are finalizing the video submission.

[Read More]Week Six Update

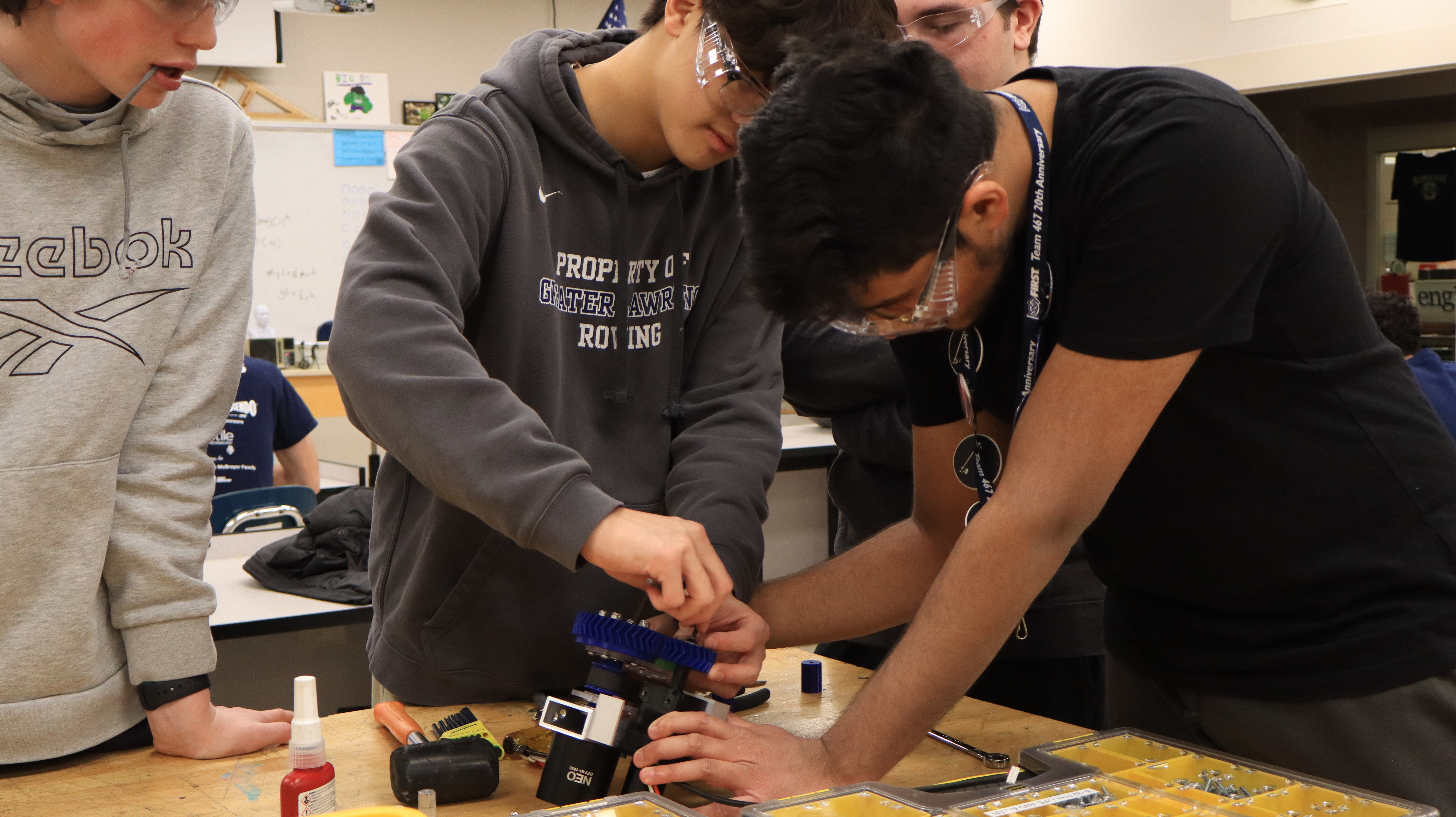

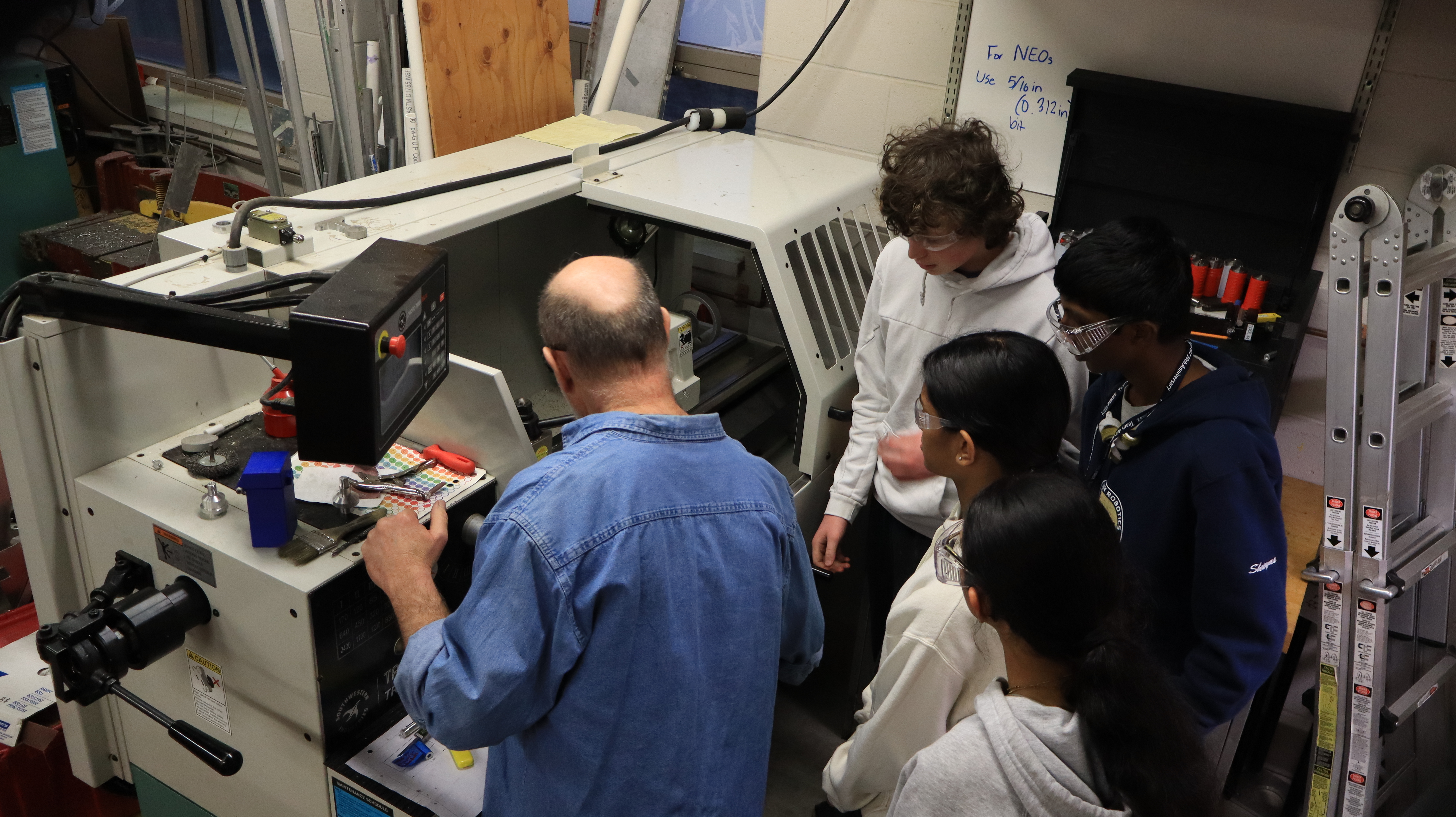

467 dealt with many ups and downs during Week 6, which comes as no surprise as we’re continuing to grasp the intricacies of this robot. Unfortunately, we snapped a shaft in our climber mechanism, temporarily halting testing. However, our machining team was on top of things and manufactured a new shaft immediately.

In addition, we accidentally ran the wrong code for our elevator, causing a very unscheduled disassembly. This demonstrated the key failure points of the mechanism, which soon strengthened mechanically. Despite these setbacks, 467 bounced back with renewed excitement to fix and complete the robot to give programming the time they need to complete and test the code. As repairs were made and wiring was completed, programming received the robot once more and has been tireless in their pursuit of controlling the robot. We are steadily making progress towards being ready to compete. The outreach team shared a similar level of dedication, completing the proof binder and presentation script. While 467 has endured many struggles recently, we still strive to be competitive at the Southern Maine District Event!

[Read More]Week Five Update

It’s been 5 weeks since kickoff, and in two weeks we will be at our first competition of the season in Falmouth, Maine! The robot is nearly complete, but some fine-tuning is needed. Both programming and electrical have been working to get the robot moving, although we’ve had occasional mechanical issues, such as with our elevator clutch.

While these setbacks hindered our progress, they progressed our iteration process and forced us to continue making improvements. Machining is complete for our entire robot and the shop is now working to finish our homemade AprilTag mounts and remanufacture parts that needed to be altered. Heading over to our outreach subteam, our Impact presenters are finalizing their script and starting their presentation prep. The rest of our Impact team is hard at work on the proof binder to validate all our presented information. We faced challenges along the way but have persevered and are excited to be back on track. See you next week!

[Read More]Week Four Update

We’re already halfway through the build season and our team is moving at a good rate! The shop is continuing to work through the large list of drawings required for all the parts on this robot. While our large industrial machines are crucial to the production of our robots, our 3D printers are equally important, working on smaller elements with filament courtesy of our generous sponsor, Polymaker.

We were able to get some of our key subsystems mounted to the robot and prep the rest for mounting next week. We had a few slip-ups using the wrong length bolts and some interference issues between mechanisms. However, with the help of our captains and team leads, we were able to spot these issues and correct them, crucially ensuring that we wouldn’t run into them later on. We are close to handing off the robot to our programming and electrical teams to get the robot up and running. We would like to congratulate our Impact team for finishing the Woodie Flowers and Impact essays. Not only this, but the Impact presentation is close to completion and is nearly ready for its first round of edits!

[Read More]